| 786 Boiler at Historic Machinery for

restoration. |

Photo: John Mandell |

| Old stay bolts being drilled out. |

Photo: Historic Machinery |

| Fire box area |

Photo: John Mandell |

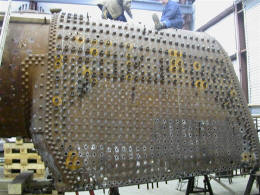

| Back sheet of the firebox |

Photo: John Mandell |

| Left wrapper section removed, exposing the mud

ring |

Photo: Historic Machinery |

| New lower left wrapper sheet welded in place,

ready for mud ring rivets. |

Photo: Historic Machinery |

| Mud Ring rivets completed |

Photo: John Mandell |

| Section of new stay bolts |

Photo: John Mandell |

| A few diagonal brace rivets had to be replaced,

with limited access. Some creative tooling was used to back & drive

the rivets. |

Photo: Historic Machinery |

| Inside the fire box, the crown sheet is

undergoing repairs. The shoulders, or radial sections, are being replaced with new plates

and stay bolts. |

Photo: Historic Machinery |

| Old shoulders are cut out |

Photo: Historic Machinery |

| New shoulders have been patterned and

fabricated, ready for installation. |

Photo: John Mandell |

| New shoulders in place, ready to be welded in.

This completes the crown sheet repairs and pretty much buttons up the inside

of the firebox area of the boiler. |

Photo: Historic Machinery |

| Driving hot rivets in the mud ring |

Photo: Historic Machinery |

| Red-hot rivets - Hot work |

Photo: Historic Machinery |

| Another person is on the inside of the firebox

backing up the hot rivet. |

Photo: Historic Machinery |

| Driving hot rivets is heavy work |

Photo: Historic Machinery |

| Another completed repair of the wrapper roof

sheet, top left side |

Photo: Historic Machinery |

| New side sheet fabricated and ready for

installation on the right side wrapper |

Photo: Historic Machinery |

| Super Heater Header being removed, allowing

removal of the dry pipe |

Photo: Historic Machinery |

| Lapping the superheater header unit seats, the

connection between the superheater header & tubes. |

Photo: Historic Machinery |

| The superheater header seats are machined and

then polished at a 45 degree bevel. The superheater tubes end in a

spherical seat. The 2 photos are of a seat that has been partially

machined & polished. A gauge ball and some dye is used to indicate the

point of contact. The top photo indicates only 3 points of contact -

no good! After more work, the lower photo shows an almost continuous

line, nearly ready for a good seal. The goal is one unbroken line

indicating a good seal. |

Photo: Historic Machinery |

| Machining the dry pipe face

|

Photo: Historic Machinery |